Packaging Block

Packaging

Om Sai Pharma Pack is a Integrated (Primary & Secondary) Unit set up in Haridwar, Uttarakhand.

The Promotors of this enterprise are a group of technocrats with experience of the Pharma space of over 35 years and a decades experience in the Plastic Packaging/Tubing and Printing Space.

The Integrated Campus is housed in a 2 acre facility with a covered area of over 2 Lakh sq. feet of first class construction.

The plant has standalone as well as integrated facility to manufacture the following inputs upto the finished products stage.

- Offset Duplex Carton Printing Unit.

- Tube Laminate/Sticker Printing Unit.

- Aluminium & Plastic Barrier Laminated Tubes (ABL)

- Fully Equipped Quality Control Department.

- Product Development/Research Module.

We print Laminates as per customer specs and design. Our customers get all service from us from designing to in-house printing, development of primary packaging materials saving huge transport costs to move inputs from various vendors and coordinating various inputs.

With the growing formulation market in INDIA, packaging has become a very important part of marketing in pharmaceutical as well as cosmetic/Healthcare industry. Since we have been over three decades old in formulation Business, We understand the basic need and technicality of packaging involved for the success of the product.

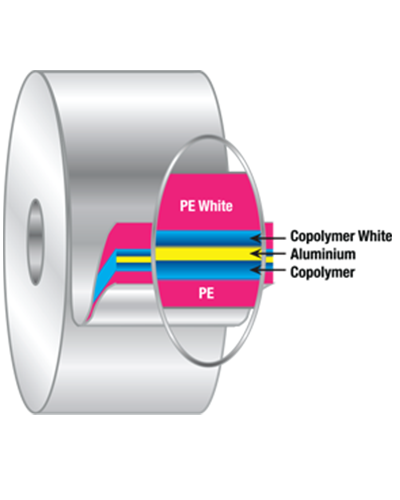

Our input materials including Laminates and plastic granules are from world leaders in the respective inputs. The lamitubes attract variety of applications throughout the world like packaging of oral care products like toothpastes, pharmaceutical ointments, cosmetic creams, food-processed products like jams, sauces etc. The structure of lamitubes i.e. the laminate which comprises of aluminium layer along with plastic polymers provides excellent barrier properties against permeation of gases like oxygen, and also the aroma/flavour of the product is retained inside the pack for the shelf life of the product. Also, the packaged product does not attract strong odors from outside environment & protects against Sunlight.

Lamitubes or Laminate Tubes

(Fully Automatic European Lami Tube Manufacturing Machine)

- 12 Micron Aluminium layer with 250 Micron overall thickness of laminate.

- 12 Micron Aluminium layer with 275 Micron overall thickness of laminate.

- 20 Micron Aluminium layer with 275 Micron overall thickness of laminate. (For higher barrier properties used for highly reactive formulation & overall appealing looks)

lnitially ABL Tube were used in toothpaste industry, but nowadays they are found useful in various pharmaceutical, cosmetic, food-processing industries with lower cost advantage & higher barrier properties as compared to Plastic-PE tubes.

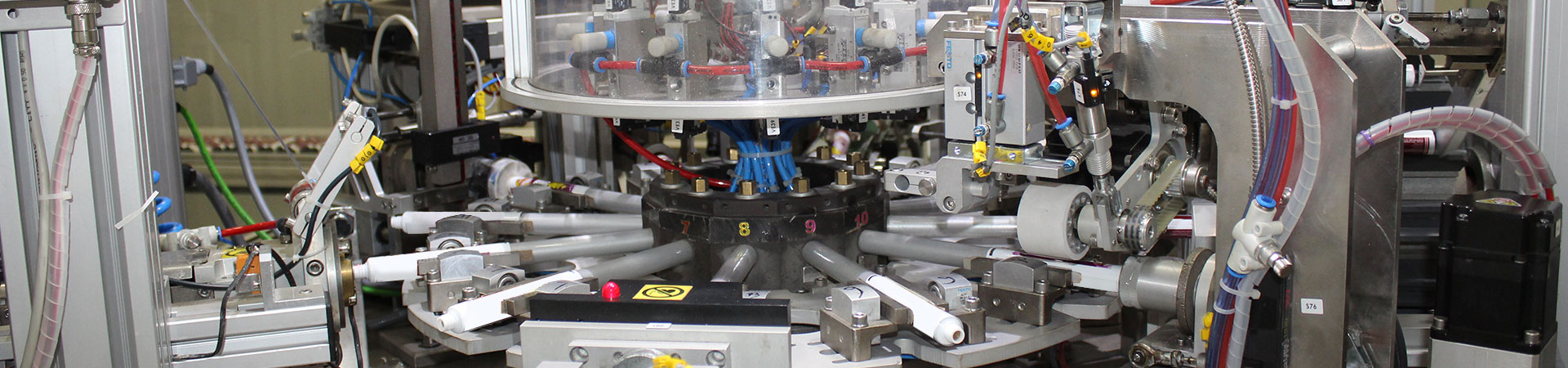

Aluminium Barrier Laminate as well as Plastic Barrier Laminate Pharm/Cosmetic Tubes are made on Swiss Tubing Machines. The environment is controlled at Class 100,000 with minimum human intervention. Robots control the whole process to ensure clean primary packaging tubes for use in Pharma/Cosmetics.

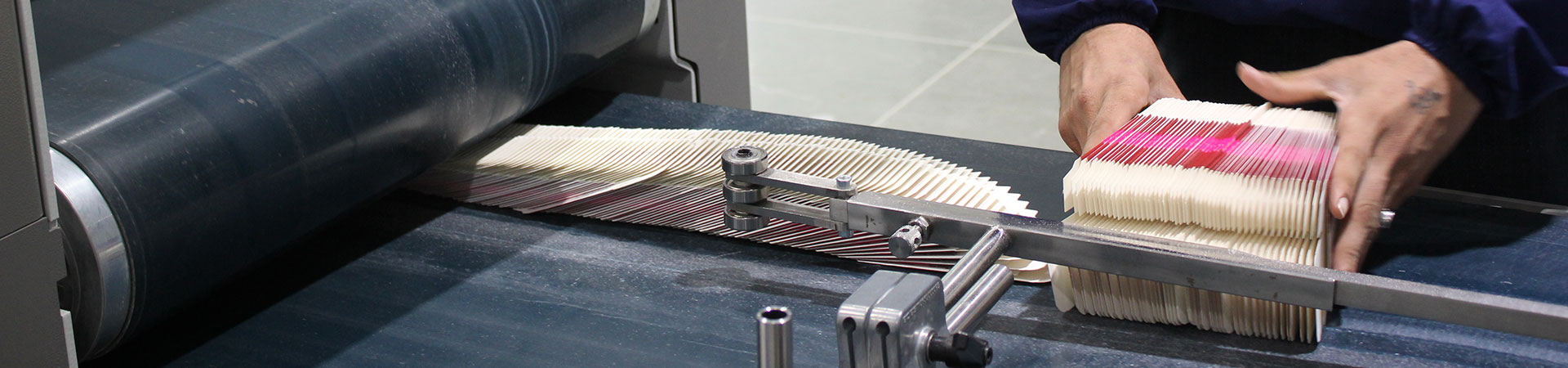

Offset & Laminate Printing

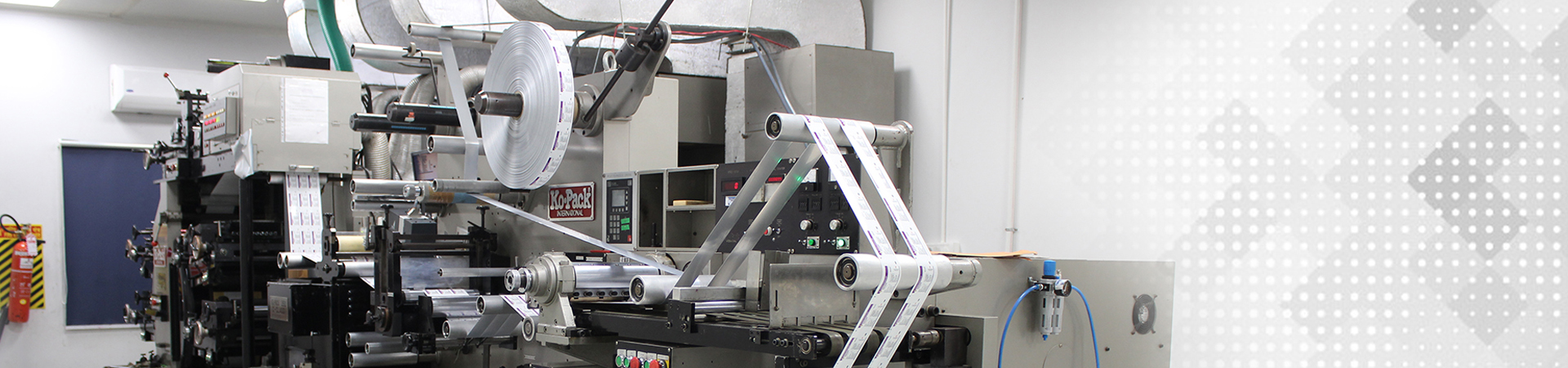

We are equipped with state of the art Heidelberg Offset Presses, BOBST Die Cutters, UV Coaters etc. Laminate Printing for ABL/PBL Tube upto 7 colors is achieved on KOPACK Letter Presses.

Infrastructure & Utilities

The Plant is maintained for air quality thru a series of Air Handling Units; Chillers; automated Fire Fighting Controls; Generator Sets, Steam Boilers, Effluent Treatment Plants; Solar Clean Energy; Material handling equipment. High Speed Material transfer Lifts.